SPOILER ALERT!

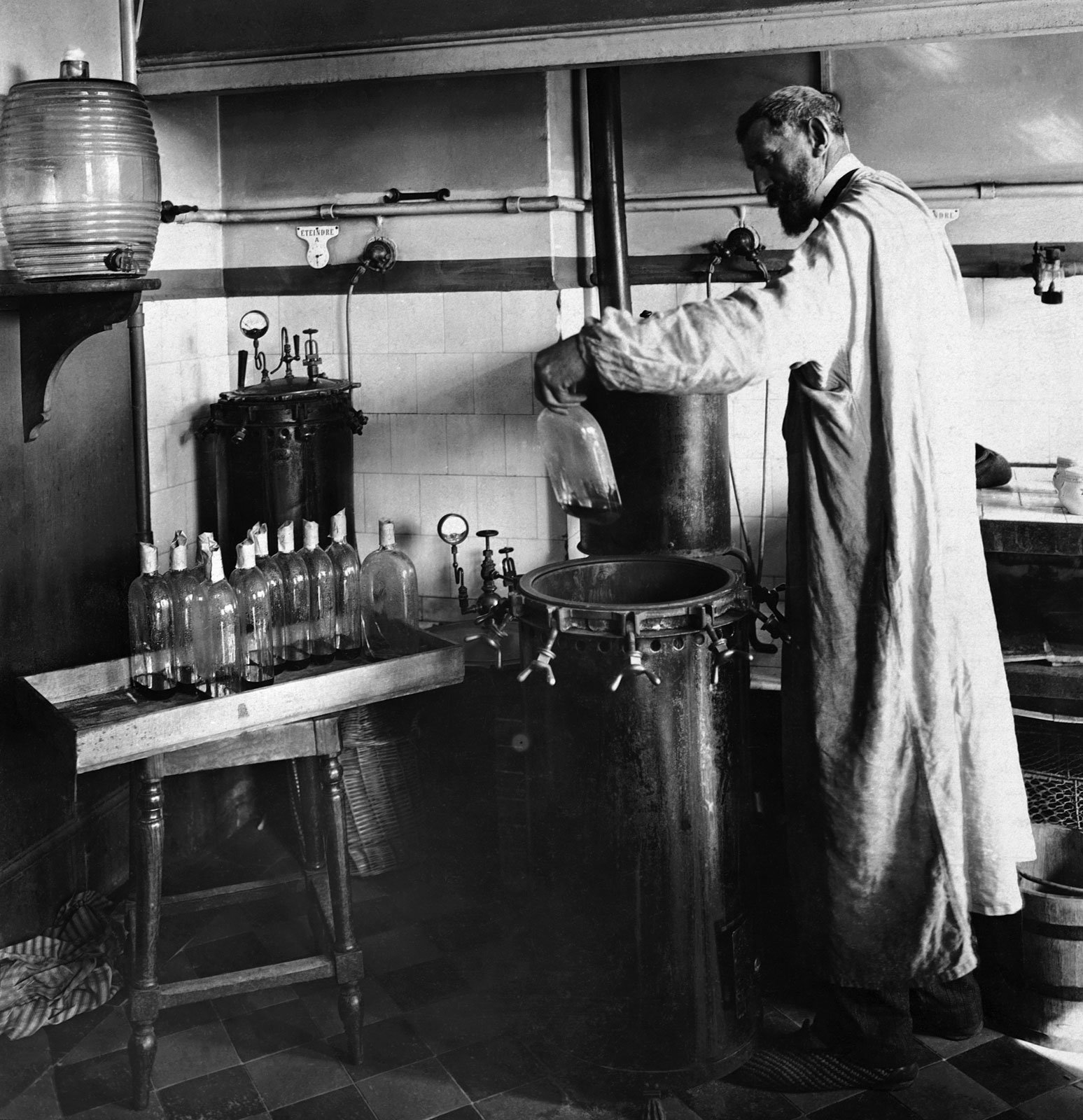

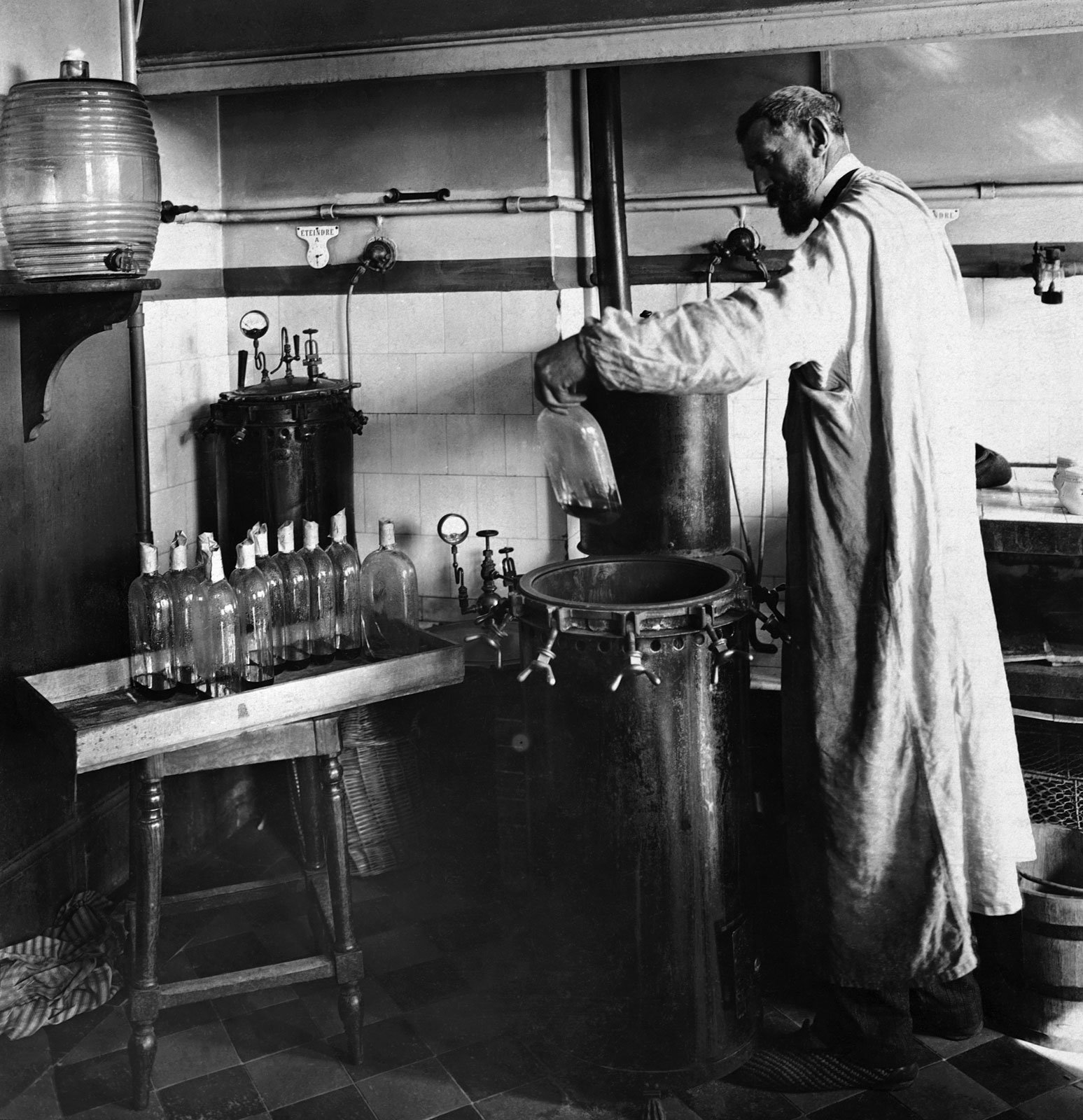

Tunnel Pasteurizers Are Highly-Effective Pasteurization Options For Foods As Well As Drinks

Created by- https://www.wtvm.com/2020/02/04/borden-dairy-releases-statement-over-pasteurized-milk/ are ergonomic and also lasting, and also they make use of an unique control software application to make best use of performance and minimize water use. This makes sure a high degree of hygienic efficiency. The compact design offers easy availability to the elements, enabling easy cleansing as well as substitute of inlet displays. Tunnel Pasteurizers can additionally be used in mix with hot filling up strategies, including warm loading technology.

The Tunnel pasteurizer process removes residual microorganisms from food and also beverages. They are effective and can be found in different sizes to match various demands. source web page are made use of in the food and drink industries to eliminate microorganisms, stop fermentation, as well as give shelf security. However, they undergo high mechanical anxiety and also temperature level variations, and also broken containers can cause damage to the equipment. PRO Engineering/Manufacturing has actually been providing the industry with quality Tunnel pasteurizers for decades and has actually developed several kinds and sizes.

Tunnel pasteurization is useful for carbonated beverages, which may have a long life span in between production as well as intake. Some drinks rest on shelves for weeks before being eaten. They can likewise travel fars away, investing a period in a cabinet or refrigerator after acquisition. Therefore, Tunnel pasteurization aids preserve quality and taste of these beverages. The procedure is additionally advantageous for vulnerable packaging, including glass as well as aluminum cans. The sudden change in temperature can bring about the tear of these containers, that makes it needed to apply the necessary preventative measures.

Tunnel Pasteurizers can be made use of to pasteurize drinks without chemicals. They use a warmth resource, raising the number of temperature level zones and also minimizing microbes. The temperature level is elevated till the required pasteurization temperature is attained. When the pasteurization procedure is total, the drink is cooled down to avoid any potential damage.

Tunnel Pasteurizers are not only used in drink production, but also in the beer sector. Its warm exchange feature helps recuperate energy through different temperature level areas. Its optimized nozzle system ensures great heat exchange with the product. In addition, Tunnel pasteurizers include water-saving features. They collect the water collected during the pasteurization process, while additionally maintaining high sanitary requirements.

Tunnel Pasteurizers are a perfect selection for large production procedures. These systems are a cost-effective, user friendly choice to sterile filtration as well as flash pasteurization. They can additionally protect against degeneration of taste. Some models include automatic stop devices to avoid overpasteurization. They likewise come in various sizes as well as dimensions. They can be customized to fulfill details client requirements.

Temperature sensing units are a crucial attribute of pasteurization systems. They are utilized to figure out the pasteurization values. These measurements are done using a formula that computes the PUs. Tunnel Pasteurizers have the ability to keep an eye on the water temperature level with high precision. Furthermore, they are developed for long-lasting use. For the very best outcomes, temperature level sensors ought to be positioned at crucial points. Furthermore, calibration systems must tape-record temperature level as well as pressure within the process shipment system.

A tunnel pasteurizer can be utilized for massive manufacturings that have high filler rates. In these cases, a passage pasteurizer is required to avoid microbe exposure to the downstream devices. Using this technology will certainly allow production lines to keep the finest quality standards and also eliminate risk of contamination.

The Tunnel pasteurizer process removes residual microorganisms from food and also beverages. They are effective and can be found in different sizes to match various demands. source web page are made use of in the food and drink industries to eliminate microorganisms, stop fermentation, as well as give shelf security. However, they undergo high mechanical anxiety and also temperature level variations, and also broken containers can cause damage to the equipment. PRO Engineering/Manufacturing has actually been providing the industry with quality Tunnel pasteurizers for decades and has actually developed several kinds and sizes.

Tunnel pasteurization is useful for carbonated beverages, which may have a long life span in between production as well as intake. Some drinks rest on shelves for weeks before being eaten. They can likewise travel fars away, investing a period in a cabinet or refrigerator after acquisition. Therefore, Tunnel pasteurization aids preserve quality and taste of these beverages. The procedure is additionally advantageous for vulnerable packaging, including glass as well as aluminum cans. The sudden change in temperature can bring about the tear of these containers, that makes it needed to apply the necessary preventative measures.

Tunnel Pasteurizers can be made use of to pasteurize drinks without chemicals. They use a warmth resource, raising the number of temperature level zones and also minimizing microbes. The temperature level is elevated till the required pasteurization temperature is attained. When the pasteurization procedure is total, the drink is cooled down to avoid any potential damage.

Tunnel Pasteurizers are not only used in drink production, but also in the beer sector. Its warm exchange feature helps recuperate energy through different temperature level areas. Its optimized nozzle system ensures great heat exchange with the product. In addition, Tunnel pasteurizers include water-saving features. They collect the water collected during the pasteurization process, while additionally maintaining high sanitary requirements.

Tunnel Pasteurizers are a perfect selection for large production procedures. These systems are a cost-effective, user friendly choice to sterile filtration as well as flash pasteurization. They can additionally protect against degeneration of taste. Some models include automatic stop devices to avoid overpasteurization. They likewise come in various sizes as well as dimensions. They can be customized to fulfill details client requirements.

Temperature sensing units are a crucial attribute of pasteurization systems. They are utilized to figure out the pasteurization values. These measurements are done using a formula that computes the PUs. Tunnel Pasteurizers have the ability to keep an eye on the water temperature level with high precision. Furthermore, they are developed for long-lasting use. For the very best outcomes, temperature level sensors ought to be positioned at crucial points. Furthermore, calibration systems must tape-record temperature level as well as pressure within the process shipment system.

A tunnel pasteurizer can be utilized for massive manufacturings that have high filler rates. In these cases, a passage pasteurizer is required to avoid microbe exposure to the downstream devices. Using this technology will certainly allow production lines to keep the finest quality standards and also eliminate risk of contamination.